BASIC UV LED SCREEN PRINTING EXPOSURE BOX

INTRODUCTION

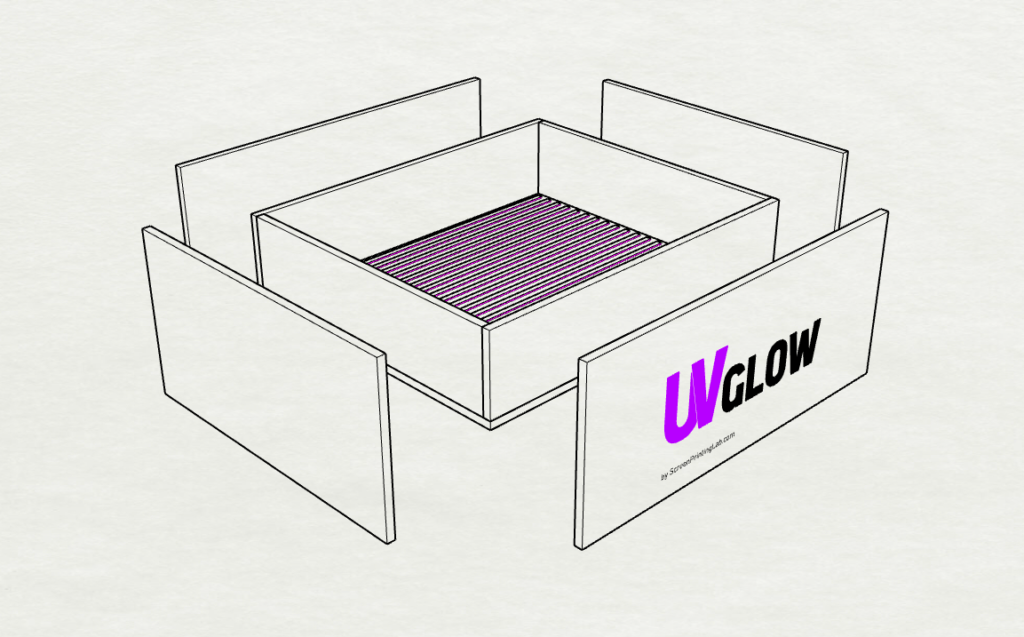

Welcome to our DIY UV LED exposure unit for screen printing. In this post, we’ll provide a detailed step-by-step tutorial on how to create your own exposure unit for screen printing at an affordable cost. We’ve carefully chosen easily accessible materials and standardized dimensions for the UV LED base, measuring 60cm x 80cm for Europe and 24 inches x 40 inches for the US. These dimensions are convenient and will suit the most common screen size of 50cm x 60cm (20″ x 40″). To make the process even more accessible, we’ll use readily available UV LED lights. Our focus is on practicality and cost-effectiveness. Let’s explore the process together and build a reliable UV LED exposure unit for your screen printing needs.

The UV GLOW DIY LED Exposure Box serves as a budget-friendly LED exposure unit tailored for screen printing enthusiasts. This versatile project is available for free download, and we are committed to helping you achieve your desired size by either expanding or reducing the box dimensions. Our emphasis lies in a design that prioritizes simplicity and affordability, utilizing materials with standardized dimensions that are widely accessible. This prudent choice significantly reduces both the cost and effort associated with material cutting, as we rely on readily available off-the-shelf components.

To facilitate your DIY journey, we have meticulously crafted a comprehensive, step-by-step tutorial. It encompasses a detailed material list that not only lists the necessary components but also provides information on where to source them. Furthermore, we offer expert product recommendations and exact specifications, ensuring that your build closely replicates our design. This meticulous approach guarantees a seamless and cost-effective construction process, enabling you to create an exposure box that meets your specific needs and budget constraints with ease.

PARTS LIST

We selected the most easy to source materials at the lowest cost. The UV LED base was selected to be 60cm x 80cm for Europe and 24 inches x 40 inches for the US as it is the easiest size to find and it will fit the most common screen of 50 cm x 60 cm / 20″ x 40″.

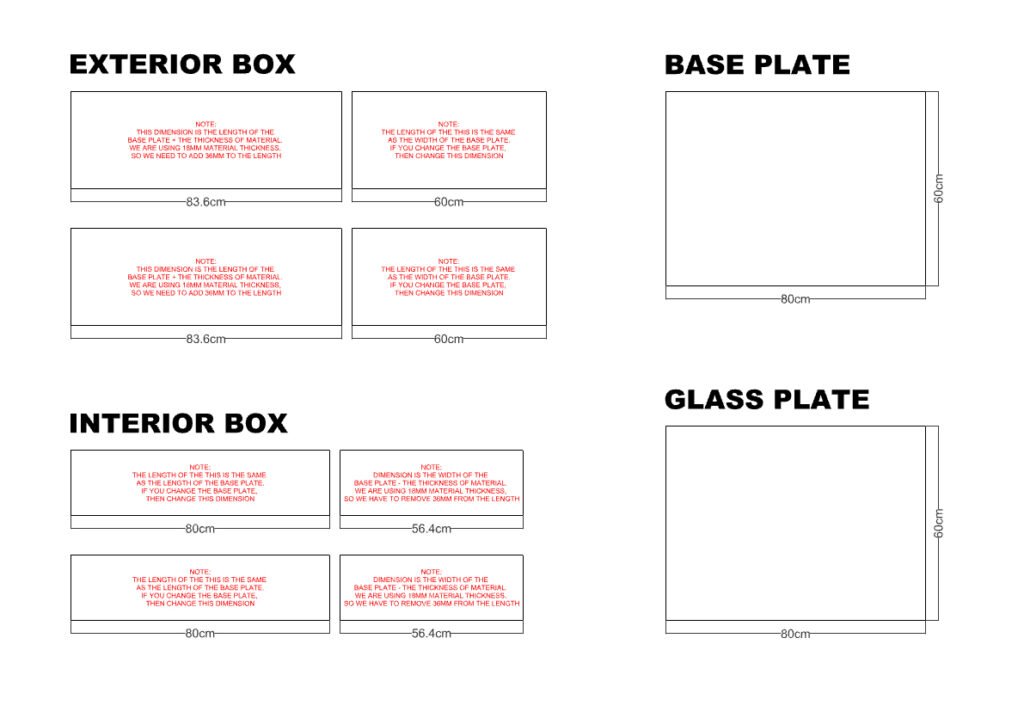

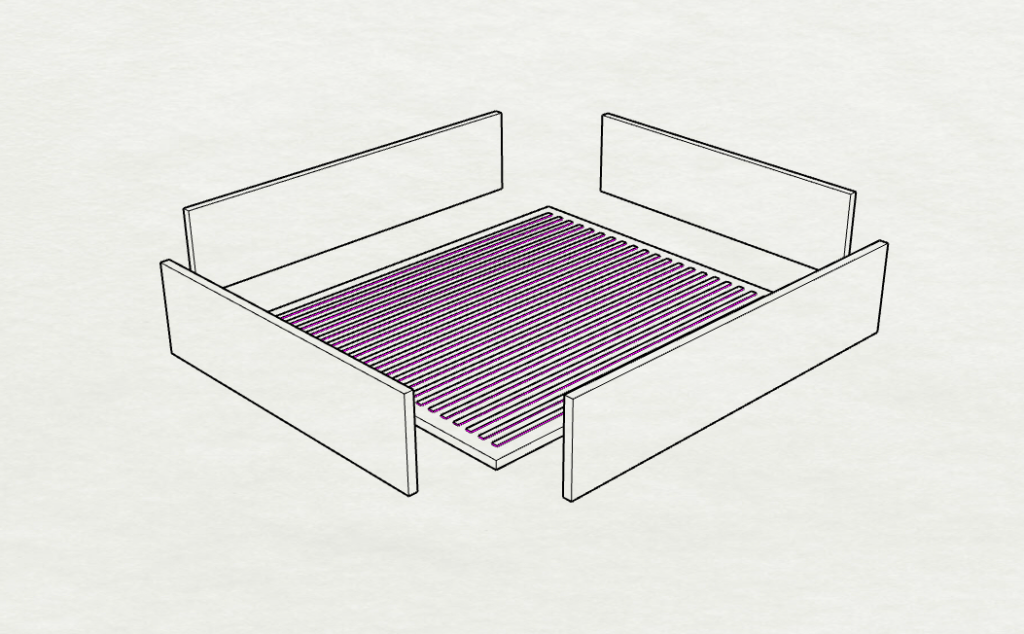

PARTS FOR THE BOX

Below you can find the dimensions of the box and cut list needed to make it. It consists of an exterior box and an interior box with base plate on which the LEDs will be affixed. The design is completely scalable. You simply need to take the size of the base plate and add the thickness of the material you find to the length of the external box and subtract the thickness of the material from the width of the internal box. For example, if you wnat to make a smaller box and use a smaller base plate of say 40cm x 50cm, you will need to add 36mm to the length of the long dimension of the outer box. This dimension will be 50cm + 3.6cm = 53.6cm. And you will need to subtract 36mm from the width of the inner box. This dimension will be 40cm – 3.6cm = 36.4cm. In our case, we could find very cheap glass and a base plate which was ready to buy without cutting. This dimension is larger than our most used screens of 50cm x 60cm and therefore suitable for us. If you use smaller screens or larger screens you can think about scaling the box up or down. Of course you can also get any size of wood or steel or whatever else you wnat to use and get it custom fabricated or cut to length. Also any glass supplier can cut any custom dimensions. We simply chose a standard available size to show that you can make it as cheap as possible with readily available materials and minimal amount of cutting / custom fabrication, so that anyone can be able to make it.

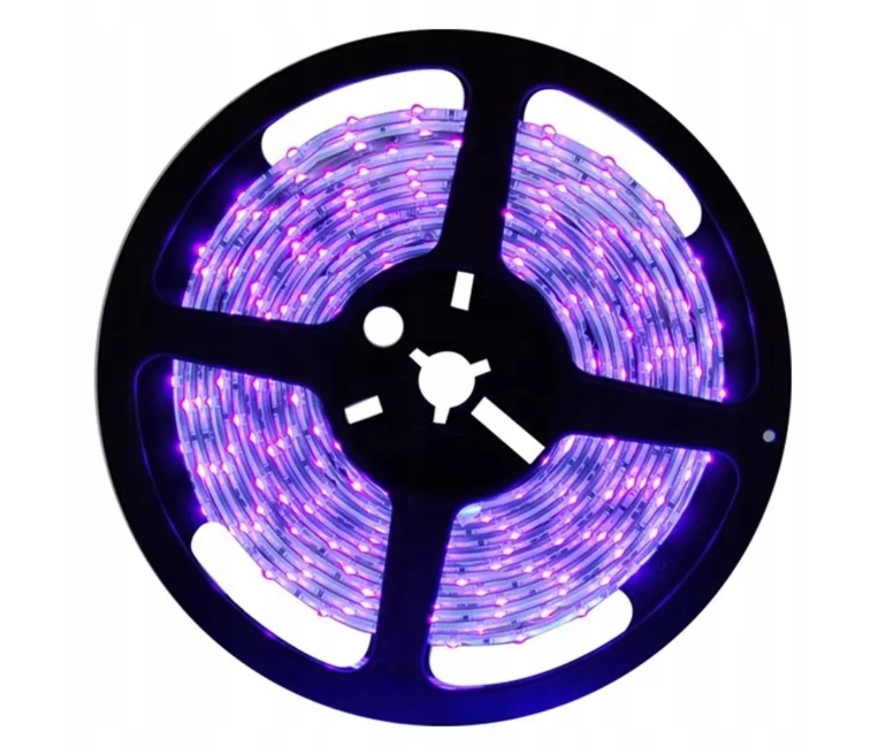

THE LEDS (LED STRIP 300 UV Ultraviolet 5050 12V 5 meters)

We selected the strongest UV LEDs we could find which are 14.4W/m and came in rolls of 5 meters for an overall 72 watts per 5 meter roll. We decided to array 15 meters of LEDs to give it as much light as possible. Fewer LEDs are an option, however it may increase the exposure time. We want to have something powerful enough to be able to expose our image as fast as possible and decided to go with 21 rows of LEDs, 3 sections of 7 rows. And we selected UV LEDs with a wavelength that is safe for your eyes. This is UV LEDs that are between 395-405 nm.

LED INFORMATION:

- Superbright 5050 SMD UV ultraviolet LED, high intensity and reliability

- Flexible LED strip

- LEDs are 14.4 watts per meter for a total of 72 watts for the 5 meter roll

- 60 SMD UV ultraviolet LEDs per meter, total 300 LEDs for 5 meters

- Self-adhesive back with double side adhesive tape

- Can use regular IP20 LEDs (IP30-IP65 will be waterproof, but unneccesary for this application).

- Maintenance free, easy installation

- Every 3-LED cutable without damaging the rest strip (typically cuttable every 5cm)

- Flexible ribbon for curving around bends

- Ultra-bright but running at low temperature

Input volts: DC 12V (12V 5A for 5meters 5050 300LED light strip)

Viewing Angle: 120° – 140°

Wavelength: 395-405nm

Long life span: 50,000 hours

THE ASSEMBLY

We selected the most easy to source materials at the lowest cost. The UV LED base was selected to be 60cm x 80cm for Europe and 24 inches x 40 inches for the US as it is the easiest size to find and it will fit the most common screen of 50 cm x 60 cm / 20″ x 40″.

SOURCING MATERIALS

We selected the most easy to source materials at the lowest cost. The UV LED base was selected to be 60cm x 80cm for Europe and 24 inches x 40 inches for the US as it is the easiest size to find and it will fit the most common screen of 50 cm x 60 cm / 20″ x 40″.